"Pipeline Pumps: Efficient Fluid Transport for Various Industries"

Introduction:

Pipeline pumps are crucial components used in a wide range of industries to facilitate effective and reliable fluid transport through pipelines. In this article, we will explore the features, functionality, and applications of pipeline pumps, highlighting their importance in fluid management systems.

Understanding Pipeline Pumps:

Pipeline pumps, also known as centrifugal pumps, are designed to facilitate fluid movement within pipelines. They utilize centrifugal force to convert mechanical energy into fluid kinetic energy, ensuring a continuous flow of liquids or gases.

Functionality of Pipeline Pumps:

Pipeline pumps play a vital role in maintaining the required pressure and flow rate of fluids within pipelines. They overcome frictional losses and elevation changes, ensuring efficient fluid transportation. These pumps find applications across various industries, including water supply, wastewater treatment, oil and gas transportation, and chemical processing.

Types of Pipeline Pumps:

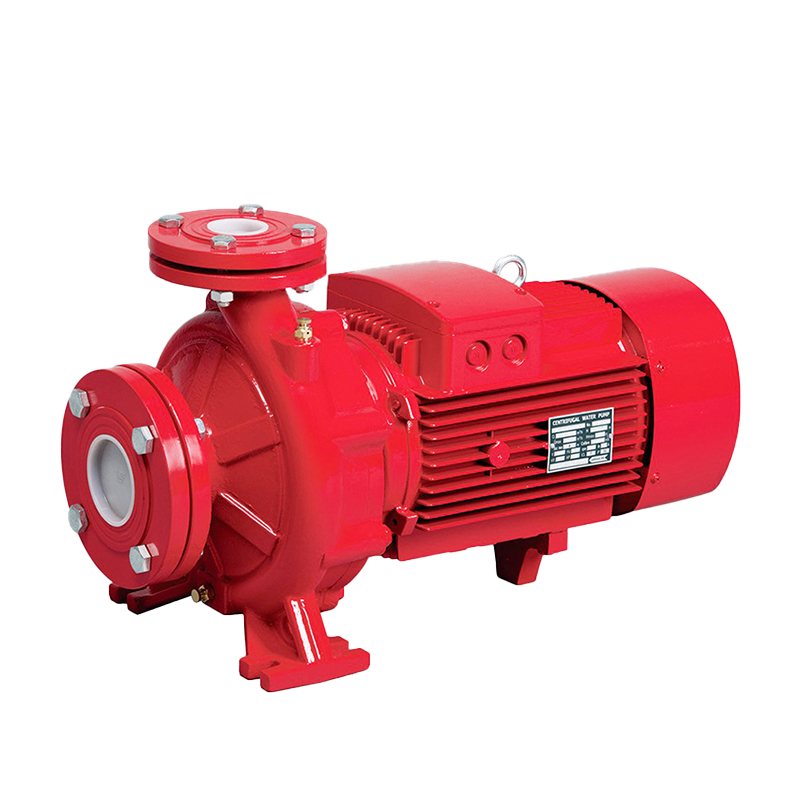

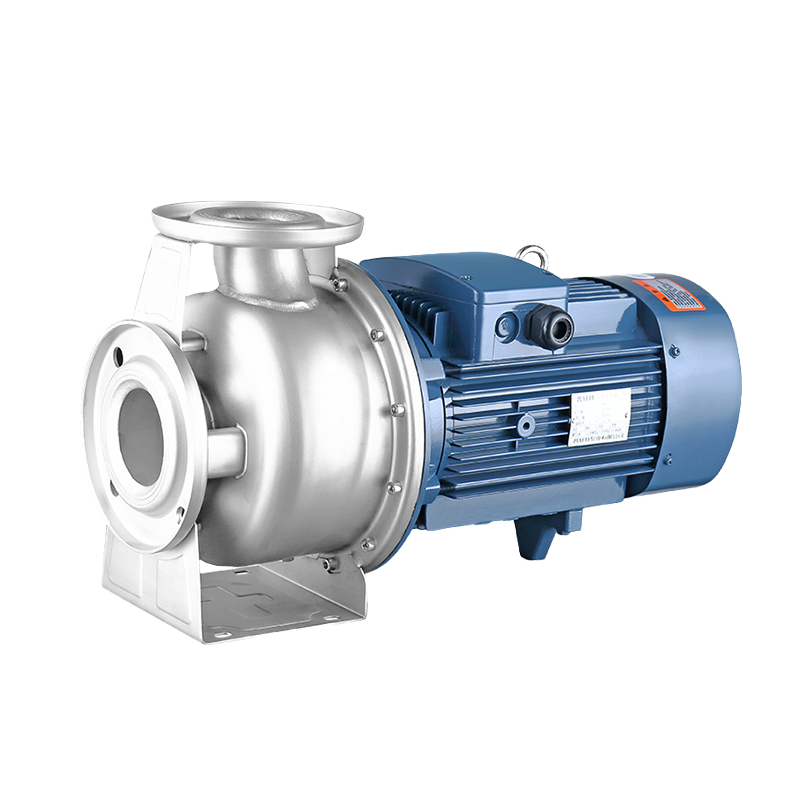

a. Single-Stage Pumps: These pumps feature a single impeller and are suitable for low to medium pressure applications.

b. Multistage Pumps: Multistage pumps consist of multiple impellers arranged in series, enabling higher pressure capabilities for long-distance pipeline transport.

c. Submersible Pumps: Submersible pipeline pumps are designed to operate while submerged in the fluid, commonly used in drainage, irrigation, and oil extraction applications.

Advantages of Pipeline Pumps:

a. Efficient Fluid Transport: Pipeline pumps ensure a smooth and consistent flow of fluids, contributing to energy-efficient operations and system performance.

b. Versatility: These pumps can handle various types of fluids, including water, chemicals, slurries, and hydrocarbons, making them adaptable for diverse industries and applications.

c. Reliability: Pipeline pumps are built to withstand demanding operating conditions, ensuring a long service life and reducing the risk of downtime.

d. Easy Maintenance: Pipeline pumps are designed with accessibility in mind, making them relatively easy to inspect, maintain, and repair, thereby enhancing operational efficiency.

Applications of Pipeline Pumps:

Pipeline pumps find extensive usage in numerous industries, including:

a. Water and Wastewater: These pumps are employed in water treatment plants, municipal water supply networks, and wastewater management systems.

b. Oil and Gas: Pipeline pumps are critical for transporting crude oil, refined petroleum products, and natural gas through extensive pipeline networks.

c. Chemical Processing: Pipeline pumps facilitate fluid transfer, circulation, and injection processes in chemical plants.

d. Mining and Construction: They are utilized in mining operations for transporting slurry and dewatering applications, as well as in construction for dewatering excavations.

Conclusion:

Pipeline pumps are essential for efficient fluid transport across various industries, ensuring the reliable movement of liquids or gases through pipelines. Their efficiency, versatility, reliability, and ease of maintenance make them indispensable for fluid management systems. By leveraging the capabilities of pipeline pumps, industries can enhance productivity, and streamline fluid transportation.

English

English عربى

عربى

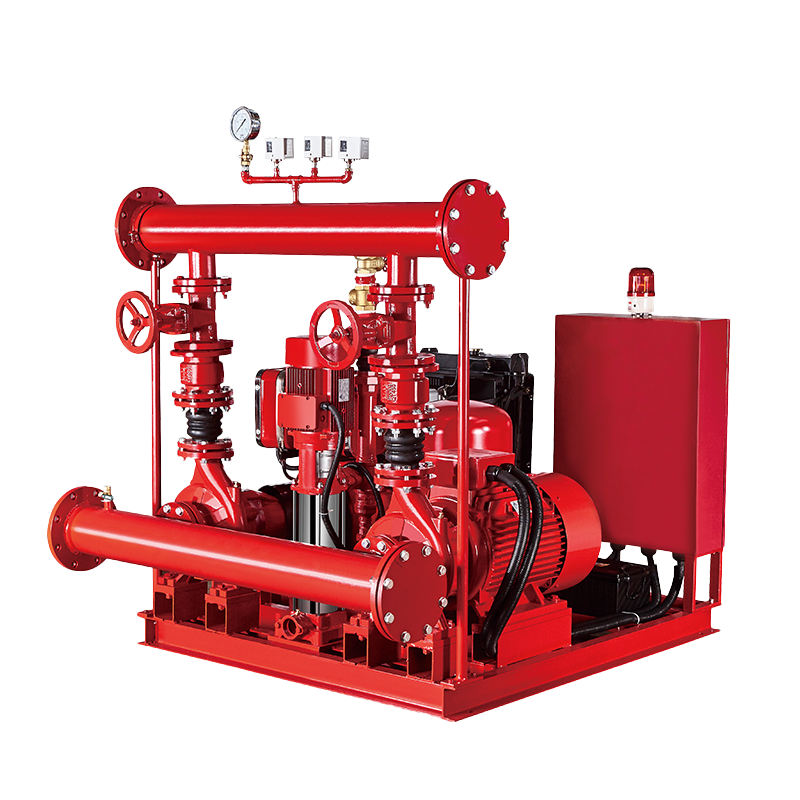

Fire Pump and System

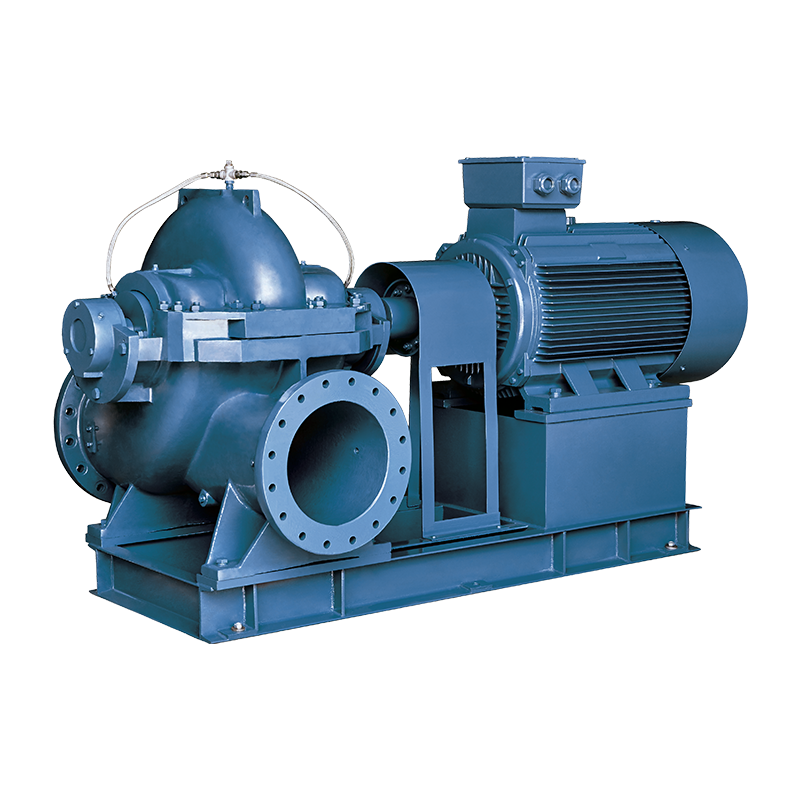

Fire Pump and System Split Case Pump

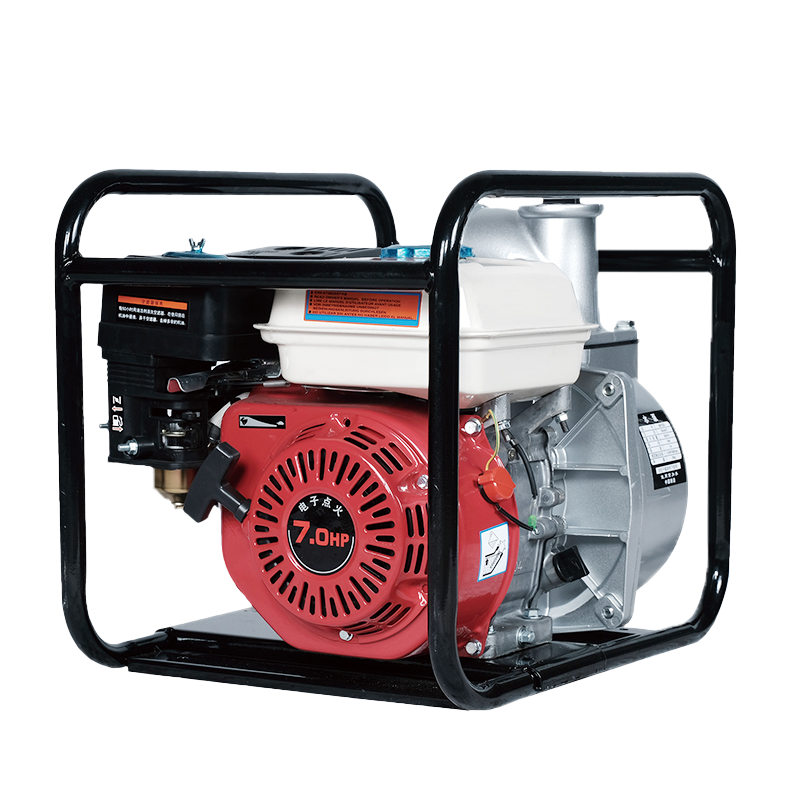

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump